Accelerated Soft Magnetic Alloy Design and Synthesis Guided by Theory and Simulation

Soft magnetic materials have use in power conversion, conditioning, distribution, and generation technologies, including transportation (electric vehicles), renewable energy (solar inverters), and aerospace (power converters and inductors) sectors. The term "soft magnet" refers to a magnetic material that easily changes magnetic pole directions using small magnetic fields. With over 20 percent of all generated electricity in the US being consumed by industrial electric motor drives, a mere 1 percent improvement in energy efficiency would result in significant financial and environmental benefits. The magnetic components are a major source of energy loss in the above-mentioned applications, motivating the need for soft magnets with better energy efficiency. The design cycle for new soft magnetic materials has so far been informed mainly by direct human engineering intuition and historic knowledge and bias, with materials development occurring by trial-and-error approaches. This Designing Materials to Revolutionize and Engineer our Future (DMREF) award supports research to establish, demonstrate, and validate a computation-guided framework for accelerated discovery of new, better performing soft magnetic materials. This approach will use computational materials science tools to guide alloy design, with the synthesis and experimental validation of properties performed for down-selected new alloys.

Publications

View All Publications

Research Highlights

Materials from Mathematics

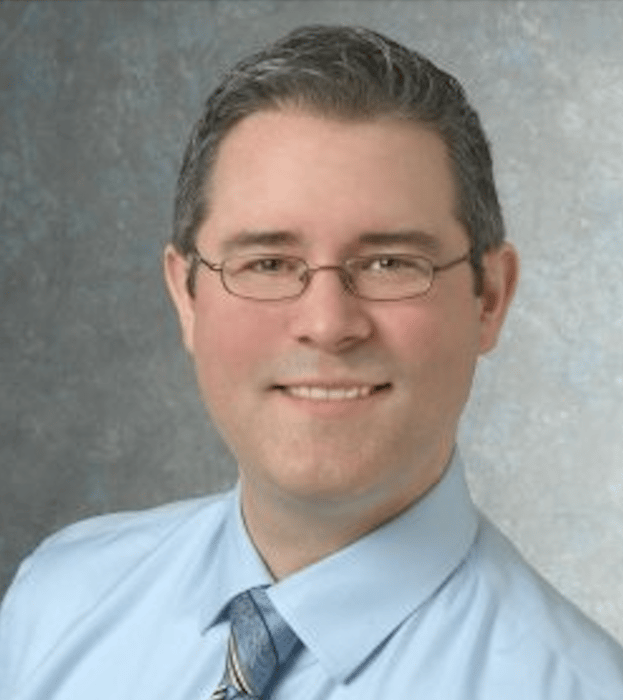

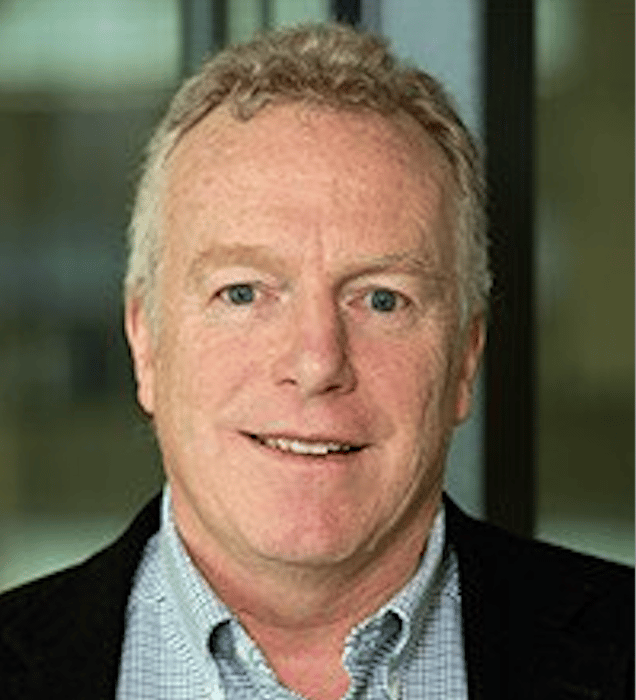

Richard D. James, University of Minnesota

8/30/2018