Rational design of redox-responsive materials for critical element separations

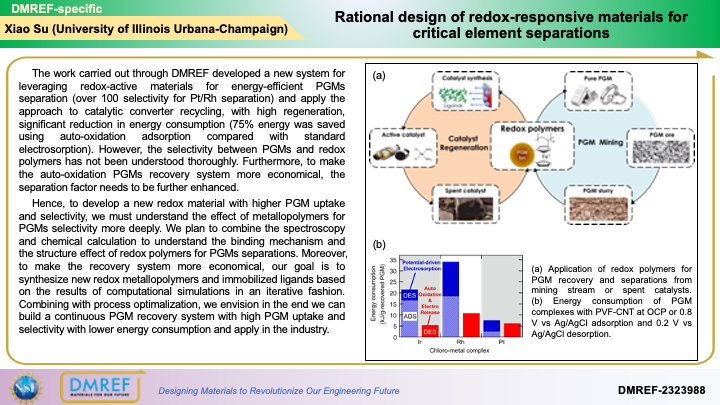

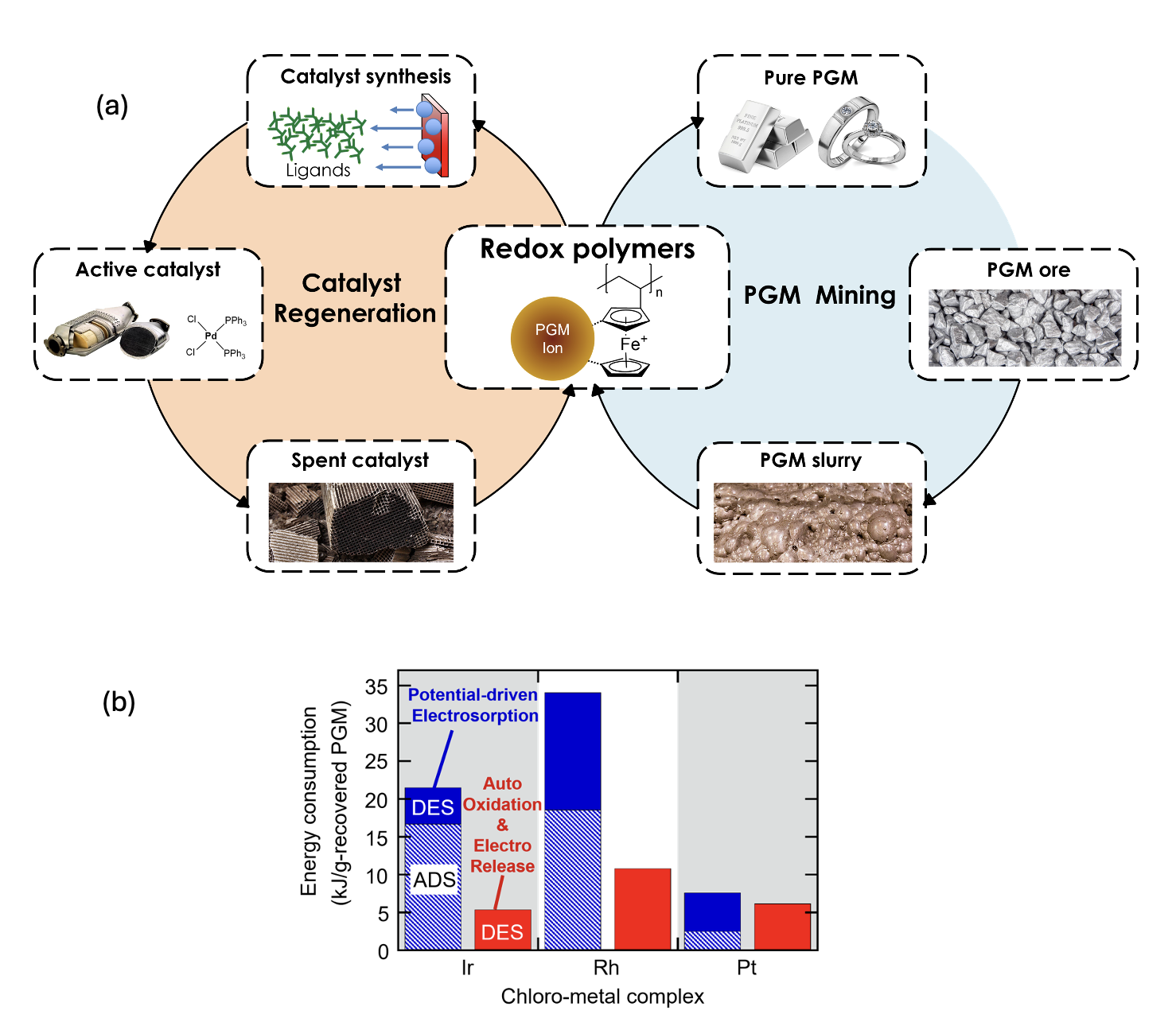

The work carried out through DMREF developed a new system for leveraging redox-active materials for energy-efficient PGMs separation (over 100 selectivity for Pt/Rh separation) and apply the approach to catalytic converter recycling, with high regeneration, significant reduction in energy consumption (75% energy was saved using auto-oxidation adsorption compared with standard electrosorption). However, the selectivity between PGMs and redox polymers has not been understood thoroughly. Furthermore, to make the auto-oxidation PGMs recovery system more economical, the separation factor needs to be further enhanced.

Hence, to develop a new redox material with higher PGM uptake and selectivity, we must understand the effect of metallopolymers for PGMs selectivity more deeply. We plan to combine the spectroscopy and chemical calculation to understand the binding mechanism and the structure effect of redox polymers for PGMs separations. Moreover, to make the recovery system more economical, our goal is to synthesize new redox metallopolymers and immobilized ligands based on the results of computational simulations in an iterative fashion. Combining with process optimalization, we envision in the end we can build a continuous PGM recovery system with high PGM uptake and selectivity with lower energy consumption and apply in the industry.